- ZIMO Home

- ESTWGJ

- Sound Design

- STP & PfuSch

- ZCS

- ZIMO GURU (FAQ)

- Links zu Partner Websites

ZIMO Product philosophy and SPECIALS

Basic product features

Despite several generation changes in line with technical progress, features that have remained the same over the years at ZIMO include: the high performance of the system centres (command stations), the multifunctional cabs for fixed and walk-around operation, the decoders with outstanding features, and the comprehensive train control technology.

ZIMO decoders, especially sound decoders are often called the best in the world, which is probably due to the excellent driving characteristics, a rich equipment with effects and the excellent sound quality. Novel operating modes are often realised years earlier than those of the competition;

in the past, for example, regulated high-frequency motor control, feedback from the vehicle and signal-controlled speed influence

ZIMO decoders are offered in great variety, mostly about 100 types, which differ in size, outputs and load capacity, but not in performance characteristics (the software is almost identical everywhere). ZIMO does NOT take part in the price war; there are only high-quality decoders, NO "basic" types, for example no "cut-down" large-scale decoders, which in total would not only contradict the system philosophy, but would also be uneconomical.

The initial commissioning of ZIMO products - system or decoder - is, contrary to rumours, no more complicated than that of products whose sales argument is simplicity. However, to take full advantage of the possibilities, the demands on the user are perhaps a little higher in terms of planning and care during installation, etc.

ZIMO & ZIMO - between compatibility and independence

ZIMO products work together with DCC products of other manufacturers, based on the RCN standards of the "RailCommuniy" (or in America based on the "NMRA standards"). In some cases, "model railway industry standards" such as XPressNet are also supported.

This means that ZIMO decoders can be operated with (probably) all DCC digital systems - mixed with decoders from other manufacturers - and also with Märklin mfx systems. Conversely, ZIMO digital systems and controllers can also control decoders from other manufacturers that comply with the current standards.

But: ZIMO does NOT follow the demand that "pops up" from time to time, according to which all products that are on the market (or played a role a long time ago) must be usable and interchangeable with each other. This idea is supposed to ensure that the individual model railroader could put together the most inexpensive components (for example, command stations, control units, various modules) as needed. In ZIMO's opinion, however, product development based on the premise of "total compatibility" does not necessarily deliver the optimum result.

ZIMO offers a range of products which on the one hand have a high degree of conformity to standards, but on the other hand contain "SPECIALS" which are only effective in combination with the appropriate counterpart (from ZIMO itself or a manufacturer who has joined ZIMO methods, e.g. HLU). Therefore, the statement applies: ZIMO & ZIMO is even better.

The - independent - "ZIMO & ZIMO SPECIALS"

and the importance of "RailCom" - for SPECIALS and general operation

Every ZIMO decoder is more than just a "normal" decoder. Capabilities that are ahead of their time or even unique make the difference. The hardware is not primarily optimised for cheapest production, but for highest performance and expandability. Because the additional software required for "ZIMO & ZIMO SPECIALS" needs space in the programme memory and computing power in the controller.

For most "ZIMO & ZIMO SPECIALS" the feedback from the decoder via RailCom is indispensable. This condition has been fulfilled by ZIMO decoders (all types, from Z and N to large scale) for 15 years already. Not only the SPECIALS, but also very simple things like writing & reading CVs without a programming track and controlling the vehicles in operation are only possible this way. Renouncing RailCom would be an anachronism - which, however, is still widespread especially in the LGB sector ... .

|

HLU = Halt - Low speed - Ultraslow, formerly "signal-controlled speed influence", From the beginning (1980), an early form of HLU, the "signal-controlled speed influence " has been integrated into all ZIMO digital systems and decoders, since 2005 with the speed limits "Full speed", "Halt" and 5 speed limits in between, as well as function control. The crucial idea is the interaction of HLU and DCC; as is well known, DCC is the communication format from the digital centre to the vehicles. The single DCC command is spread over the whole layout, due to the contained vehicle address (only) a certain decoder reacts. HLU is a second communication channel, from an electronic unit to the vehicles located on isolated track sections. HLU instructions (unlike DCC instructions) can differ from track section to track section, especially regarding speed limits. They do NOT have an address and apply to any ZIMO decoder. Vehicles or trains are brought to a stop before red signals or to obey speed limits by HLU instructions. The HLU instructions are generated at the track section outputs of StEin modules, usually computer-controlled, and added to the DCC data stream: DCC instructions are identical on all track sections, HLU instructions vary according to the operating situation. HLU data reach the decoders almost without delay because they are sent out approx. 100 times/sec. |

|

OW = Ost-West, die Ergänzung der Vorwärts/Rückwärts Richtung, Since the model railway has gone digital, the direction set on the driving device is not track-related, but locomotive-related: Forward = "cab 1 ahead". This is often, but not always, advantageous. The ZIMO system, together with ZIMO decoders, therefore offers the possibility to drive specifically in a given layout-related direction, called "East" and "West", if required. This direction of travel can also be interpreted as "right" and "left"; technically it is the phasing of the DCC track signal. Characteristic for the procedure is: the entire directional logic is NOT changed over, but "forward-backward" and "east-west" are used at the same time. These "both directions" are sent via RailCom to the control unit so that the full information can always be displayed WITHOUT losing the usual handling (change of direction). This results in being able to start correctly without knowing the direction of the rerail. |

|

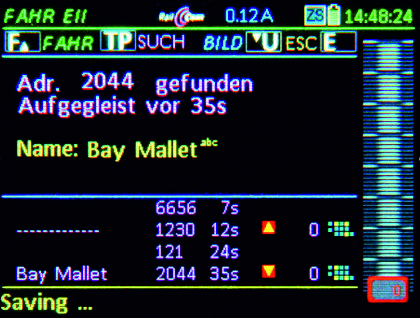

The ZIMO on-track search The "on-track search" was introduced in 2018 for ZIMO systems and decoders. It is used to determine previously unknown addresses of a vehicle. The vehicle being searched for is briefly de-energised (tilt for 2 sec or set anew on the layout); after starting the procedure from the cab (controller), the address and (if available) the name of the vehicle found appear. This usually happens within seconds and also works for several vehicles (addresses). The on-track search is a useful feature of ZIMO control technology - by its very nature "ZIMO & ZIMO", but also already included in the RCN-217 standard of the manufacturers' association "RailCommunity". |

|

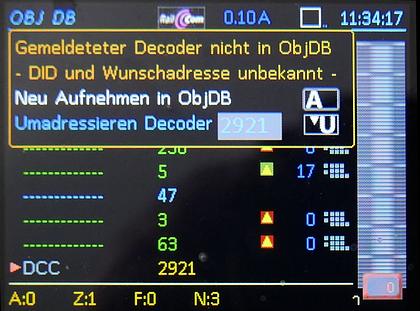

Registration according to RCN-218 and GUI transmission The registration, which used to be announced as ZIMO stock search and has meanwhile been realised in a modified form according to the RCN-218 standardised by the "RailCommunity", is initiated at the ZIMO cab (controller) MX33. Thereupon (new) decoders report in a statistical procedure by RailCom messages "LOGON". A comparison is made with the existing "object database" (the " stock") in order to register which decoders are still present, which are missing and which are new. The "GUI transmission"* from a decoder into the system is perhaps even more important in practice than the "stock search" or "registration" described above. It is started either immediately afterwards or independently, it is also done via the RailCom feedback channel. *) The "GUI" (Graphical User Interface) consists of an individual collection of images, symbols and control elements for each vehicle, which enable the locomotive (train) to be controlled from the control unit (cab/controller, app, ...). |

01.02.2023