- ZIMO Home

- Sound Design

- ZCS

- ZIMO GURU (FAQ)

- Links zu Partner Websites

|

The MX10 Command Station Go here . . . for information pages about the "associated" MX33 Cab (controller) The MX10 or MX10EC (the EConomy version) is the central unit of the digital multi-train control system from ZIMO, in other words: the "Digital Centre" or according to the traditional ZIMO designation as a "Command Station". The ZIMO command station: not a big "box", but modern technology: At first glance, you see the very small dimensions (depending on type 18 or 15 cm wide, 3 cm high), and the lack of heat sinks and fans. Thanks to state-of-the-art power electronics - five high-frequency switching regulators for track outputs and supply voltages - the device does not run hot, despite 20 A (MX10EC: 12 A) on the track and 5 A on the bus (continuous load!). The ZIMO system takes care of applications where high currents could cause damage (N-gauge, etc): thanks to special circuitry which manage shorts on the track when connected to the MX10, and there are fewer sparks than on many weaker digital control systems.

But the ZIMO system offers more than "a lot of power": The processor,

memory and software inside, plus the quality measurement technology for

precision RailCom detectors (for example),

plus many connections and a standard integrated radio system make the ZIMO

typical advanced functionality possible. |

Command station MX10EC

Command station MX10 |

|

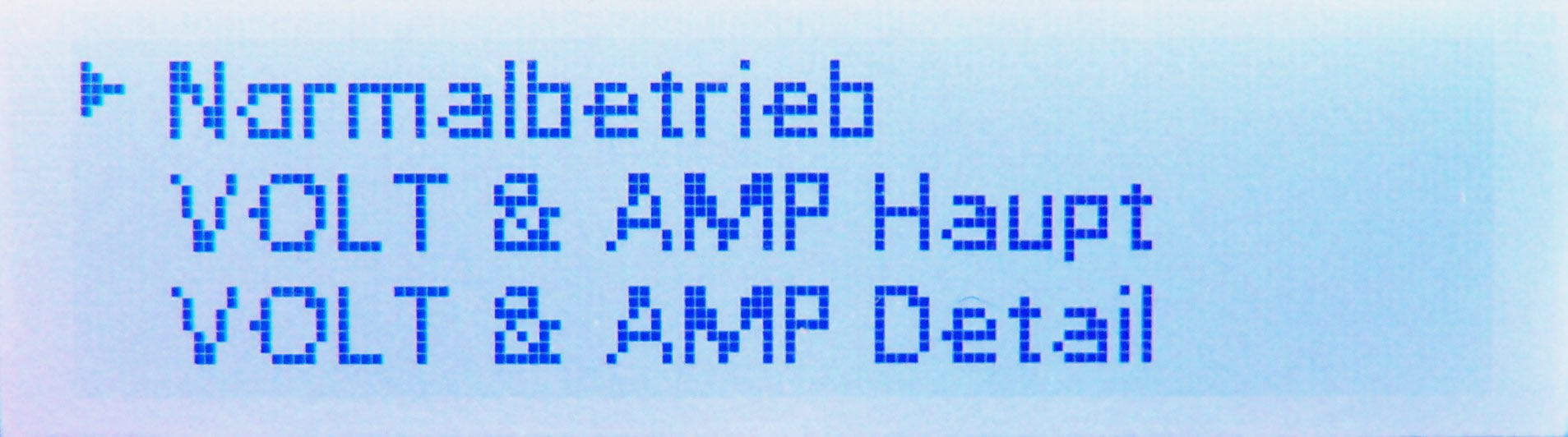

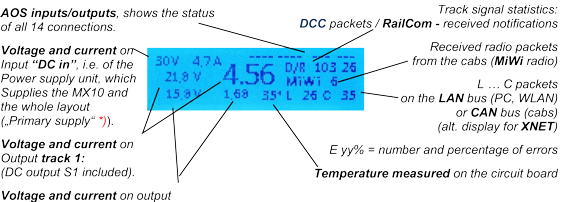

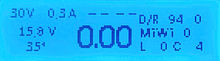

MX10 Front View:

The "Normal screen" and its display panels

Setting screens for voltage and current values (VOLT & AMP Master and Detail) . . . . . .Short Circuit Display (OVC) . . Drive Screen . . . . . . . . . . . . . . . Menu for "BaseCab" Functions .

MX10

Rear View: |

|

|

The important technical data:

|

|

|

Typical system configurations consisting of MX10, MX33/-FU cabs and MX32, Stationary

Setup Modules of "StEin" class  |

|

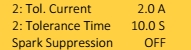

Primary Power Supply, Driving Voltage and Driving Current The necessary primary power supply comes from an external power supply (NO transformer), which (without supply through transformers) means a significant reduction of the power loss and heat compared to the "old" devices. Therefore, the high output power (up to 600 W) is available with a very compact design. The voltage to the track outputs as available in a wide range - stabilized and fully adjustable in fine steps (0.1V), and of course, protection from higher voltages and short circuits is installed - from 10 to 24 V, the main output ("Track 1", or "Schiene 1") delivers a maximum continuous operating current of 12 A, the second output ("Track 2", or "Schiene 2") 8 A; the latter can also be used as a programming or decoder update track. The current limit adjustable is in fine stages (0.1A). An important feature is the adjustable threshold time in the case of over-current or short-circuit - via fast circuits to prevent cut-outs from little shorts on frogs, etc.. Moreover, not only the absolute current, but if necessary the device can also detect differential overcurrent ("OVC adaptive"), so a shutdown occurs at sudden power increases, even though the absolute threshold has not been reached, which contributes mainly at small scales (N, TT, ...) to protect the wheels and pick-up shoes in the case of a short circuit. |

The Power Supply (30 V, 240 Watt), |

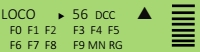

Track Protocols and Data Management DCC (NMRA or VHDM specification) is the standard protocol of the MX10. However, hardware and software are open for expansion to MOTOROLA (MM, the Märklin digital track signal) and other standards, if such a need exists, especially for faster methods of data transfer. Of course, the possibilities of standardized protocols are fully exploited, so for DCC there are 10239 locomotive addresses, 2048 accessory addresses (each with 4 sub-addresses), 14/28/128 speed steps, 28 functions, etc. |

|

|

RailCom and ZIMO "Train Number Impulse" (In German = Zugnummernimpulse = "ZACK") "Bi-directional communication" using "RailCom" is an integral part of all relevant components within the ZIMO system. The MX10 is equipped with two "RailCom Global Precision Detectors", one for each of the track outputs. "Global" means that it detects all those RailCom functions that are independent of the current position of the vehicle; "Local detectors" deal however with the address detection in single track sections. "Precision" means that reception and evaluation of the RailCom messages is carried out not only by the standardized thresholds, but that the RailCom signal is analyzed to decipher also attenuated and distorted RailCom signals and to be readable in (such a case) even on large systems. The global RailCom messages are on the one hand utilized to increase the efficiency of data transfer to the decoders (to put it simply: RailCom messages are answered by DCC packets - because obviously arrived in the decoder - and do not need to be repeated). Above all, RailCom messages contain information which are then forwarded to driving devices and computers. Simple applications are: reading and display of CV values in the "Operational mode" (i.e. on the main track), ongoing display of the driving speed (real time clock) measured in the decoder, alarm signals, or (in accessory decoders) the point positions, etc. The ZIMO MX10 also recognizes the "classic" ZIMO train number pulses ("Zugnummernimpulse") sent by all ZIMO decoders (in DCC format since about 1998). |

|

Booster Solutions Due to the high track current of the MX10 (up to 20A) there is possibly a need for boosters only for fairly large layouts and/or large scales. The preferred solution is then to use another MX10, which is synchronized with the "Central MX10". The use of foreign boosters is possible, but less advantageous, because the only communication with such devices uses the outdated NMRA "Control Bus" (in practice, only simple short messages). CAN Bus (internal to ZIMO System Communications) and Bus Systems for 3rd party products On the MX10, there is (as usual for ZIMO products) two parallel-connected CAN Bus sockets (RJ-45); these are 8-pin, because besides the actual 6-pin CAN Bus, more connections are needed for a "sniffer" (front socket) or for booster and StEin module control. Another socket (front) contains the X-bus (especially for ROCO Lokmaus and similar devices), the connection of third-party products such as S88, Loconet (Fred's) is forseen. Wireless communication with ZIMO Cabs (controllers) The MX10 is equipped with a Wi-Mi module. Mi-Wi is a variant of the "ZigBee" standard in the 2.4 Ghz band, which is approved worldwide, and provides a higher data throughput than the 344 MHz band previously used by ZIMO. Potential disadvantages compared to 344 MHz band with respect to the penetration inside buildings are compensated by the network capability. LAN connection for Wi-Fi enabled input devices and as an alternative to a computer interface Mobile phones and tablets (with suitable apps installed) can be used to control a layout via a wireless router connected to the LAN socket of the MX10, or via a connection to the home network. The same LAN socket can also be used as an alternative to the USB interface for computer communication (advantage: more computers on the line). USB (host) socket on the front panel for USB sticks and Micro USB (client) socket on the back (MX10 only) The USB (host) socket, is used to plug in a USB

stick, from which the updating of the software in the MX10 can be done. Long experience (with the MX31ZL and MXULF) shows that the use of a USB stick is often easier than the update from a computer because uncertainties with operating system, drivers and interfaces disappear. Alternatively, the USB (client) interface can also be used to connect a computer in order to programme a decoder with the help of software (ZCS, P.F.u.Sch., TrainProgrammer, etc.). In addition, the programmes for system control (STP, ESWGJ, TrainController, etc.) also communicate via the USB (client) interface. The MX10 as Stand-alone Device - Digital Centre Users who put no value on a "physical" hand controller, can use the computer with appropriate software (eg ESTWGJ, STP, TrainController, ADaPT, ...), and use phones and tablets, to control the layout , without "real" connected Cabs (controllers) In developement: The MX10 as a Decoder Update Device In the future the MX10 can be used in two ways for a decoder update: 1) The decoder update collection file ("Sammelfile") or sound projects are put on a USB stick and the decoder update or sound project loading is handle via the USB (host) socket. 2) The decoder update process is performed by connecting the MX10 via the USB (client) socket to the computer, so MX10 as just an interface between the computer and decoder. |

|

|

RailCom is a Trade Mark of Lenz Elektronik GmbH. Last update:26.07.2024 |