MN NON-SOUND DECODERS

for

small scales (Z to H0) |

|

|

|

|

|

|

|

|

|

|

|

Standard H0 |

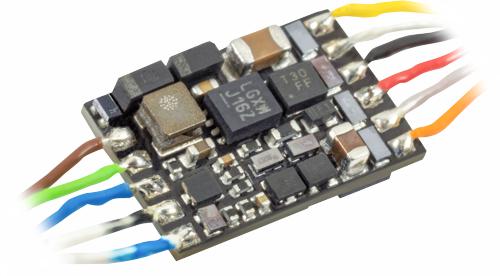

Miniature (N, TT, H0e, H0m, small H0,...) |

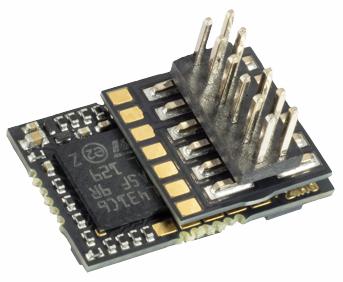

Sub Miniature |

Next interface |

E24 interface |

PluX12 (& E24) |

Low Voltage |

DECODER FAMILIES

Typen (by connection type) |

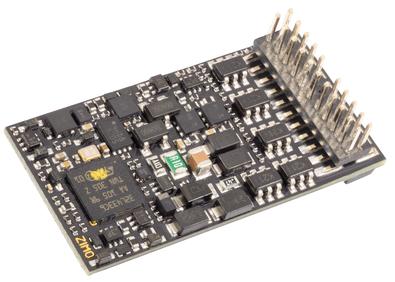

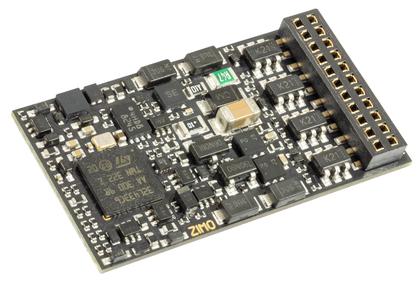

MN330

MN330R |

MN330P22

|

MN340C

MTC acc. to VHDM std. |

MN340D

MTC variant ZIMO |

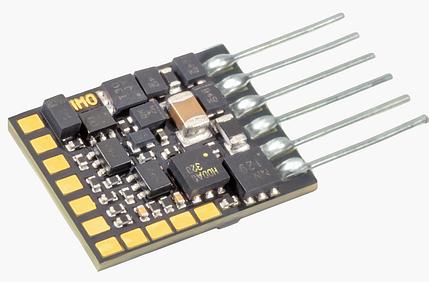

MN300

MN300R, MN300F |

MN300P16 |

MN170

MN170R, MN170F |

MN170N |

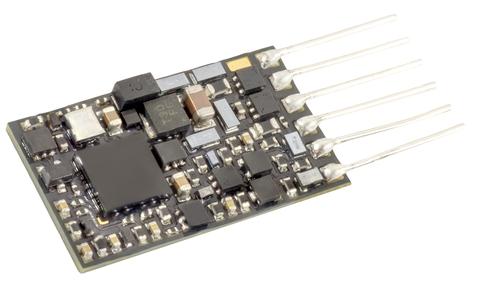

MN160 |

MN160N, -L |

MN150 |

MN150N |

MN180N18 |

MN140E24 |

MN140P12 |

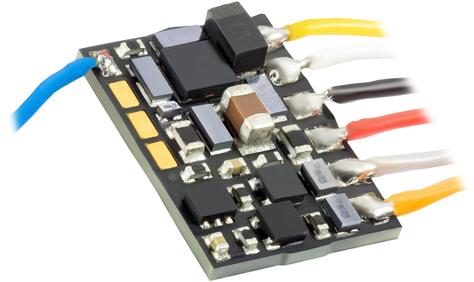

MN250 |

| |

Permitted operating modes |

DCC

mfx

MM

AC

DC

|

DCC

MM

AC

DC

|

DCC

MM

DC

|

DCCMMACDC

|

DCC

MM

DC

|

|

Dimensions (mm) |

30 x 15.3 x 2.2

single-sided assembly! |

30 x 15.3 x 2.2

single-sided assembly! |

28.6 x 15.3 x 2.5

single-sided assembly! |

28.6 x 15.3 x 2.5

single-sided assembly! |

17.6 x 10.5 x 3.1 |

17.6 x 10.5 x 3.1 |

12 x 8.6 x 2.3 |

12 x 8.6 x 2.3 |

13 x 7.5 x 1.6

single-sided assembly! |

13 x 7.5 x 1.6

single-sided assembly! |

8.2 x 5.9 x 2.1 |

8.2 x 5.9 x 2.1 |

13.3 x 9.5 x 2.6 |

13.5 x 8.7 x 2.3 |

13.5 x 8.7 x 2.8 |

9.9 x 7.5 x 2.1 |

| |

The dimensions of decoders with standardized interfaces (PluX, MTC, NEM-651, Next18) correspond to the corresponding standards by VHDM and NMRA or are smaller. In case of the wired decoders, which are protected by a shrinking tube, the indicated dimensions are WITHOUT this tube, because it can be taken off, if there is not enough space.

|

|

|

Connections |

11 wires

NEM-652 |

PluX22 |

21MTCFO3, FO4, FO5, FO6

logic level (std.) |

21MTCFO3, FO4, FO5, FO6

"amplified" outputs |

11 wires

NEM-652, NEM-651 |

PluX16 |

9 (resp. 7/6) wires

NEM-652, NEM-651 |

NEM-651directly |

7 wires |

NEM-651directly |

7 wires |

NEM-651directly |

Next18 |

E24 |

PluX12on adapter |

11 wires |

| |

The indicated number of stranded wires for the decoders refers to the free wires of the fully wired variants. -R and -F variants have NEM-652 or NEM651 connectors, which take up part of the wires; the N variant of the MN170 (NEM-651 direct) and all PluX, Next18, MTC and E24 types carry out the connections via the respective pins or plugs.

MN150: 7 free wires (2x motor, 2x track, front light (FO0f), rear light (FO0r), common positive)

MN150N: 6 pins (2x motor, 2x track, front light (FO0f), rear light (FO0r)), no free wires

MN160: 7 free wires (2x motor, 2x track, front light (FO0f), rear light (FO0r), common positive)

MN160N, -L: 6 pins (2x motor, 2x track, front light (FO0f), rear light (FO0r)), no free wires

MN170: 9 free wires (2x motor, 2x track, front light (FO0f), rear light (FO0r), common positive, FO1 FO2)

MN170R: 7 wires on 8-pole plug (2x motor, 2x track, light front (FO0f), light rear (FO0r), common positive), no free wires

MN170F : 6 wires on 6-pin plug (2x motor, 2x track, light in front (FO0f), light in back (FO0r), 1 free wire (common positive)

MN170N : 6 pins (2x motor, 2x rail, light front (FO0f), light rear (FO0r), no free wires

MN250: 11 free wires (2x motor, 2x rail, front light (FO0v), rear light (FO0r), FO1, FO2, +5V, Goldcap -, Goldcap +), common positive on the capacitor

MN300 and MN330: 11 free wires (2x motor, 2x rail, light front and rear (FO0f, FO0r), FO1, FO2, common plus pole, ground, capacitor positive pole)

MN300R and MN330R: 8 wires on plug (2 motor, 2 track, light front/rear (FO0f, FO0r)), FO1, common positive), 3 free wires (FO2, ground, capacitor positive)

MN300F: 6 wires on plug (2x motor, 2x track, light front/rear (FO0f, FO0r)) and 5 free wires (FO1, FO2, ground, common positive, capacitor positive) |

|

|

Total current (continuous)

motor+FOs(peak) |

1.2 A(2.5 A) |

1.2 A(2.5 A) |

1.2 A(2.5 A) |

1.2 A(2.5 A) |

1.0 A(1.5 A) |

1.0 A(1.5 A) |

0.7 A(1.5 A) |

0.7 A(1.5 A) |

0.5 A(1 A) |

0.5 A(1 A) |

0.5 A(1 A) |

0.5 A(1 A) |

0.7 A(1.5 A) |

0.7 A(1.5 A) |

0.7 A(1.5 A) |

0.5 A(0.8 A) |

| |

“Total current” means motor current plus current of the function outputs. Usually, the current used by the consumers on the function outputs is very low (only a few LEDs), so that the “total current” usually is available for the motor output. Therefore, the “total current” and the “motor current” are usually indicated with the same value. In case a function output has a higher continuous load (e.g. because it has a smoke generator connected) the motor output provides less current.

NOTE: The continuous load is – against common interpretation – not limited by the motor amplifier, but by the heat development on the PCB. Therefore: the smaller the decoder – the less current flows, especially less total current. |

|

|

Motor current (continuous)(peak) |

1.2 A(2.5 A) |

1.2 A(2.5 A) |

1.2 A(2.5 A) |

1.2 A(2.5 A) |

1.0 A(1.5 A) |

1.0 A(1.5 A) |

0.7 A(1.5 A) |

0.7 A(1.5 A) |

0.5 A(1 A) |

0.5 A(1 A) |

0.5 A(1 A / 5V) |

0.5 A(1 A / 5V) |

0.7 A(1.5 A) |

0.7 A(1.5 A) |

0.7 A(1.5 A) |

0.2 A / 5V(0.3 A / 5V) |

Continuous Current |

he continuous current indicates the possible continuous load at normal conditions (normal room climate and circulating air in the room where it is used). At about 100°C (212 F) on the PCB, the temperature sensor shuts down the consumers (in contrast to exceeding the peak current, at which the current sensor reacts).

At overload or overtemperature, the headlights start flashing at fast pace (about 5 Hz = 5 times per second). As soon as the PCB cooled down for 20°C (hysteresis), the motor is turned on again automatically.

The actual resilience of the motor is influenced by various factors, e.g. the track voltage (the higher, the more heat loss and the lower the possible continuous current), type and condition of the motor (low-ohm, etc. ) Dirt and heat from the outside are not helpful either.

ZIMO decoders can be overloaded (50% - 100% up to the “peak current”) for a short period of time. Usually, the peak current can be endured about 20-30 seconds, but only if the decoder was not at its limits beforehand. Currents in the medium area are naturally fine for a longer time, usually for a few minutes. This way, the usual hills on a model railway layout can be overcome, on the way down the hill the decoder cools down again. |

Peak Current |

While the “continuous current” refers to a long-time heat development of the decoder, the “peak current” indicates the threshold on which the current consumption (even with hypothetically perfect cooling) reaches the maximum of resilience of the motor amplifier. After reaching this threshold, it takes a few seconds or milliseconds until the decoder is shut down permanently. The fastest possible shut-down is reaching the threshold via a short circuit (depending on the type of decoder between 4 A and 10 A). ZIMO decoders possess an intelligent system, which prevents unnecessary shut-down but still is secure.

In case of a motor shut-down due to exceeding the peak current or because of a short circuit, the decoder is switched on again after about 3 seconds, but in this state it does not show any signs, like when shutting-down because of over temperature. |

|

|

Current on Function OutputsTotal of the FOs |

0.8 A |

0.8 A |

0.8 A |

0.8 A |

0.8 A |

0.8 A |

0.5 A |

0.5 A |

0.5 A |

0.5 A |

0.25 A |

0.25 A |

0.5 A |

0.5 A |

0.5 A |

0.5 A |

| |

The output current on a function output is indicated as sum (of all FOs or groups). A single output is, nevertheless, strong enough to handle the total current alone.

In case of an overcurrent, the decoder is turned off immediately, but depending on the anount exceeding the limit within a few tenths of seconds or milliseconds. This makes the cold start of light bulbs possible (if this is not enough, this can be defined within the software as “Soft Start”). |

|

|

number and type of

Function Outputs

incl. 2 x headlights (+ logic-level outputs) |

104 with wires

6 on s.pads

(+2 logic level)

(+1 alt. use IN1) |

109 on plug

1 on s.pad

(+2 logic level)

(+1 alt. use IN1) |

4all 4 on plug

(+6 logic level) |

8all 8 on plug

(+2 logic level) |

64 with wires

2 on s.pads

(+2 logic level) |

64 on plug

2 on s.pad

(+2 logic level) |

6 all 6 on s.pads

(+2 logic level) |

6 2 on plug

4 on s.pad

(+2 logic level) |

4 2 with wires

2 on s.pads

(+2 logic level) |

4 2 on pins

2 on s.pad

(+2 logic level) |

4 2 with wires

or pins

2 on s. pads

|

4 2 with wires

or pins

2 on s. pads

|

4 all 4 on plug

(+4 logic level) |

8 all 8 on plug

2 also on s.pads

(+4 logic level) |

8 4 on plug

4 on s.pads

(+2 logic level) |

4 all 4 with wires

|

| |

There are different kinds of (function) outputs:

-

“normal” function outputs, often also called “amplified outputs”, to which front lights, light bulbs, uncouplers, smoke generators etc. can be connected. Each of these “open-collector outputs” (this is the technical term) is connected to the negative pole (GROUND) of the consumer; the other side (the positive pole) of the load is connected to:

- Either the “common positive pole” of the decoder (on wires: the blue one)

- or to a low-voltage output of the decoder if it has one

- or to an external power supply (e.g. a voltage regulator which is directly supplied by the tracks)

- or (if there is no positive pole accessible, often at miniature decoders with NEM-651 interface) to one of the track poles (has the effect of reduced brightness of lights)

- "logic-level outputs" ("unamplified"), are outputs, which supply a voltage level (3.3 V / 0 V) depending on if they are switched on or off. They are supplied via an internal protective resistor (usually 10 kOhm, i.e, a maximum of 0.5 mA current). Those outputs can be used:

- Either with the help of an external amplifier, either self-made or with the ZIMO product M4000Z

- or as servo control wires (the traditional servos are compatible with the logic-level outputs)

- or as control wires for SUSI interfaces, and for I²C busses.

The typical two logic level outputs, which almost every ZIMO decoder has, are switched between the possible applications by CVs.

By factory default these "SUSI pins" are set as SUSI Clock u. Data as follows: Logic Level CV #124 bit 7=0, Reed CV #393 bit 5=0, I²C CV #394 bit 2=0, and Servo Control Line CV = 0 (CV # see line 'Servo control wires").

If you want to switch to logic level outputs, set CV #124 bit 7 = 1 (value 128). The function of the outputs is now defined and the CV values of the other possible modes listed above are ignored. If the logic level is inactive (bit 7 = 0), the next active value of the function modes in this order is valid.

Decoder with 21MTC-interface do have function outputs which are either logic-level or amplified:

The decoders MN340 are available as “C” or “D” types. The variations “C” and “D” differ (like all ZIMO MTC decoders) in the type of FO3 and FO4, at current decoders (like MN340 or the “old” MX636) also FO5 and FO6.

“C” (the “standard” type): FO3, FO4, FO5 and FO6 are logic-level outputs, i.e. only usable with an external amplifier (e.g. loco board)

“D” (the ZIMO type): FO3, FO4, FO5 and FO6 are “normal“ function outputs and can be used directly by a consumer.

In this version the standard switching input IN2 on Pin2 is replaced by a logic level output (switchable via CV #393).

|

|

|

Servo control wires

(complete witch 5 V supply) |

2alternate use

of logic-level

(NO, external 5 V) |

2alternate use

of logic-level

(NO, external 5 V) |

2alternate use

of logic-level

(NO, external 5 V) |

2alternate use

of logic-level

(NO, external 5 V) |

2alternate use

of logic-level

(NO, external 5V) |

2alternate use

of logic-level

(NO, external 5 V) |

2alternate use

of logic-level

(NO, external 5 V) |

2alternate use

of logic-level

(NO, external 5 V) |

- |

- |

- |

- |

2alternate use

of logic-level

(NO, external 5 V) |

2alternate use

of logic-level

(NO, external 5 V) |

2alternate use

of logic-level

(NO, external 5 V) |

- |

| |

If the logic level outputs/SUSI pins are switched to servo control wires by means of CVs (see above, line "Number and type of function outputs"), commercially available servos (Graupner, Robbe, etc.) can be controlled, for which various operating modes, end positions and rotation times can be set.

A setting (CV value → 0) activates the function as servo control line (if logic level, reed and I²C are deactivated, see above).

Responsible CVs for most MN decoders are CVs #181 and #182.

The 5 V supply for the servos has to be provided externally, as far as the decoder does not have a low-voltage output.

|

|

|

SUSI connection

alternatively SUSI, I²C |

yesalternate use

of logic-level

on solder pads |

yesalternate use

of logic-level

on PluX |

yesalternate use

of logic-level

on MTC |

yesalternate use

of logic-level

on MTC |

yesalternate use

of logic-level

on solder pads |

yesalternate use

of logic-level

on PluX |

yesalternate use

of logic-level

on solder pads |

yesalternate use

of logic-level

on solder pads |

- |

- |

- |

- |

yesalternate use

of logic-level

on Next18 |

yesalternate use

of logic-level

on E24 plug

+ on s.pads |

yesalternate use

of logic-level

on solder pads |

- |

| |

By default, the SUSI signal (SUSI Data, SUSI Clock) is present at the logic level outputs (see line "Function Outputs") because bit 7 of CV#124 is not set (binary 0). By setting bit 7 of CV#124 to binary 1, the SUSI signal present there is deactivated and you can use the two pins as switchable logic level outputs if CV#181, CV#182 = 0 at the same time, because otherwise a servo control signal is present at these two pins.

The SUSI interface is used in vehicles with – partly upgraded – interfaces for data transmission, where electronics are integrated, i.e. panto drives, smoke generators, uncouplers, etc. The original idea of the SUSI interface, namely controlling external sound modules, has moved to the background, because sound decoders provide better solutions and in contrast to the past can be manufactured with smaller dimensions.

|

|

|

Switch Inputs

for cam sensors, Reed switches, i.a |

1on s.pad

+2 alternate use

of logic-level |

1on PluX

+2 alternate use

of logic-level |

2on MTC

+2 alternate use

of logic-level |

2on MTC

+2 alternate use

of logic-level |

2 alternate use

of logic-level |

2 alternate use

of logic-level |

2 alternate use

of logic-level |

2 alternate use

of logic-level |

- |

- |

- |

- |

2 alternate use

of logic-level |

2 alternative Anw.

der Logikpegel |

2 alternative Anw.

der Logikpegel |

- |

| |

Switch inputs are used to connect sensors directly or for position dependent functions.

Note: The logic-level outputs (see above) can also be used as switch inputs, if needed and the software supports functions with switch inputs (e.g. position dependent lighting effects or loco controlled commuting. This is also valid for non-sound decoders. |

|

|

stabilised Low Voltage

to be taken from |

- |

- |

5 V

max. 20 mA,

on MTC plug |

5 V

max. 20 mA,

on MTC plug |

- |

- |

- |

- |

- |

- |

- |

- |

- |

5 V

max 10 mA,

on E24 plug |

- |

5 V

max 50 mA

on wire |

| |

Some MN non-sound decoders have a 5 V low-voltage source, which is used to operate LEDs, for example. This means that less energy is "burnt" than if the LEDs were operated at full voltage via a 1.5 kO resistor, for example, and fluctuations in the track voltage are kept away from the lighting, i.e. brightness fluctuations are avoided. The power of the current available on its own solder pads is normally max. 50 mA. This is sufficient for LED lighting - but it cannot be used to operate servos!

With the MN250, the 5 V can be taken from the soldering point or stranded wire as shown on the connection diagram. Wiring diagrams can be found above in the info areas  of the respective decoder and also in the instruction manual. of the respective decoder and also in the instruction manual.

|

|

|

Energy Storage connection

15 V capacitors DIRECTLY to the decoder |

yes

with wires |

yes

on PluX |

yes

on solder pads |

yes

on solder pads |

yes

on solder pads

max 15,000 µF |

yes

on PluX

max 15,000 µF |

no

|

no

|

no

|

no

|

no

|

no

|

yes

on solder pads

max 15,000 µF |

yes

on plug

+ on s.pads

max 15,000 µF |

yes

on plug

+ on s.pads

max 15,000 µF |

yes

on wires

2 mini goldcaps incl. |

| |

A stay-alive capacitor connected to the decoder in the form of Elkos (electrolytic capacitors), Tantals (Tantal capacitors) or Supercaps (old denomination: Goldcaps) takes over the supply of the decoder and connected consumers during interruptions of the wheel-track-connection due to dirt, insulated frogs or similar. Starting with a capacity of about 200 µF a positive effect can be seen; at least 1000 µF are recommended.

In addition to preventing getting stuck or flickering lights an energy accumulator also reduces the heating of the decoder (by eliminating reactive consumption) as well as motor noise (by bridging the gaps in supply through RailCom and HLU).

|

|

*

*

expand all

|

expand all

|

collapse all

(useful to print out the complete information)

collapse all

(useful to print out the complete information)